A 20-foot container takes up approximately the same space as a large standard US parking bay.

Buy shipping containers for as low as $1,350.00! CALL US TODAY! (888) 977-9085

So you’ve bought or rented a shipping container and the delivery date has been set. This guide will cover the steps that you need to take to make sure that the delivery site is prepared and that your container can be delivered safely.

To avoid any unnecessary cost, damage, or disappointment, it’s important to prepare for the delivery of your shipping container. This means that the site needs to be prepared, the road leading up to the delivery site, and there needs to be someone available to receive the delivery.

Failure to prepare might result in you having to pay for damage, another delivery, or you could end up with the shipping container placed in the wrong position.

This is the last thing that we would want to happen which is why we encourage you to prepare as much as possible.

If you have prepared and it happens to rain causing the ground to be soft, please call us so that we can set another date for the delivery.

Here are the steps you need to take to make sure you have enough space for the delivery to happen safely and to avoid unnecessary costs or disappointment.

When choosing a suitable site, there are two things to keep in mind: sufficient space and hard, level ground.

Container space

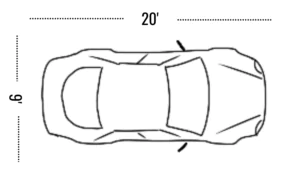

Here is an easy way to picture how much space you need.

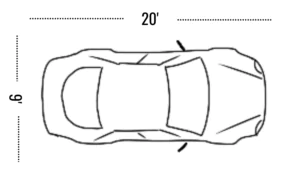

A 20-foot container takes up approximately the same space as a large standard US parking bay.

A 20-foot container takes up approximately the same space as a large standard US parking bay.

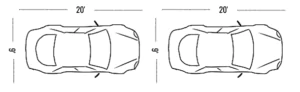

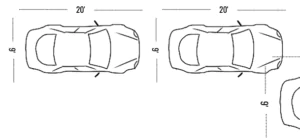

A 40-foot container will be as big as two large parking bays placed head-to-tail.

A 45-foot container will be 2 and a quarter parking bays.

To be 100% sure you have enough space, we recommend that you measure it out using a tape measure. You will then know which container size will be a good option to consider.

Expert Tip: The price of a 40 ft container is sometimes only a couple of hundred dollars more. So if you have enough space, you’ll get double the storage of a 20 ft.

Hard, level ground

Containers are heavy and if the ground is soft, they could sink on one or more sides. This might cause problems such as difficulty opening and closing the doors. It could also reduce the lifespan of your container because water might pool on the roof and eventually cause holes.

Make sure that the ground is level and hard before the container arrives.

The majority of shipping containers are delivered on the back of a tilt-bed truck. Tilt bed trucks are perfect because no additional equipment is required to offload the container. The driver only has to back into the spot, offload the container, and drive away from it.

Our drivers typically use three types of tilt-bed trucks

Roll-Bed or Flatbed Tow Truck

These trucks are typically used for 20-foot or smaller containers.

They are used for locations where space is limited.

Length: 40’ container requires 120’ for unloading. 20’ container requires 60’ for unloading. The space required is about three times the size of the container being delivered.

Expert Tip: If you do not have the required length, you can request a smaller truck. See information on truck types below.

Three times the length of the container being delivered is about the space required for delivery.

Height: 14’ high when container is sitting on the truck then increases to 21’ when unloading.

Entrance to Property: “How much space do I need for a truck to enter on my property?”

Ensure the street leading into your property is wide enough to accommodate the truck radius while turning onto your property. If there is a gate or fence or narrow driveway at the entrance of your property it must be at least 12’ wide and any overhead obstructions such as overhead wires, tree branches or structures must clear 14’. However, that alone does not guarantee that the truck has sufficient space to enter your property. Consider these things:

Culverts – are there culverts at your entrance that may inhibit the trucks back wheels from entering safely. An example would be uneven or soft ground that the trucks back wheels would be required to drive over.

Entrance Obstructions – is there anything at your entrance that would inhibit the trucks back wheels from entering onto your property. Examples of this would be; fence posts, underground utilities, pipes, planters, trees, mail box or concrete not able to withstand 30, 000 pounds.

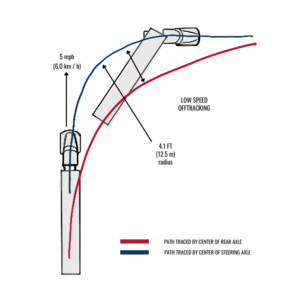

Narrow street – is the street leading into your property wide enough for the trucks radius. Larger trucks will require a wider turn radius.

The trucks back wheels have a wider turn radius than the front wheels thus requiring extra turn space.

The larger the truck the larger turn radius it requires.

Trucks Used:

Our drivers use a variety of trucks to deliver. These are a few of the possibilities. Some trucks are longer and less maneuverable than others so if you have limited space be sure to request a smaller truck.

Once a container is delivered or loaded on a truck, it is difficult and costly to turn it around so it’s important the doors are facing the proper direction on the truck when it’s delivered. When considering where you’ll place the container, keep in mind which way you want the doors to face so that you can access it properly on your property.

Most used and new shipping containers have just one set of double doors at one end. We will need to know how you want your container loaded on the truck for delivery so the container doors face the direction you need when unloaded. Keep in mind the truck will back up into the delivery pad and drop the container to the ground.

When considering your delivery, it is important not only to take into consideration the pad where the container will sit but also the entire pathway that the driver is required to take to make the delivery. Please consider the following:

Clear overhead obstructions – A loaded truck needs 14’ height clearance and increases to 21’ when being offloaded. It is important to clear any overhanging wires, branches, structures and to avoid low roofs or doorways so that the truck can easily pass through.

Clear pathway – clear out all items from your site that may obstruct the truck from easily delivering the container. This includes but not limited to equipment, vehicles, toys, trash, debris, rocks, plants, shrubs, holes, mounds of dirt, sand etc. Waiting to do this on day of delivery may result in driver wait fees.

Confirm the route to your site – Make the driver aware of any obstacles they may incur on route to your location such as but not limited to narrow bridges or roads, steep or curvy roads, unpaved or washed-out roads, low bridges or trees that they will be required to pass under or any roadblocks or closures that you are aware of. You may have to provide an alternate route if the driver deems it unsafe.

Confirm the ground is hard and dry

Stuck truck – Loaded tilt-bed trucks are very heavy, weighing close to 30,000 lbs. Therefore, it’s very important that the ground leading into the delivery site and at the delivery site is hard so that the truck does not get stuck. The customer is responsible for any cost incurred to get a truck unstuck.

Wet weather – if you anticipate wet weather on the day of the delivery it is best to reschedule in order to avoid potential problems. If it rains on the day of the delivery, then contact the container company or driver immediately to reschedule the delivery.

Level the ground ahead of delivery – The delivery site must be leveled before the driver arrives.

Difficult Doors – It is not unusual, especially with used equipment, that the container doors are difficult to open and close even if the site is level. This is easily remedied by shimming a corner of the shipping container which will adjust the door enough so the locking cams catch and close properly.

Purchase railroad ties

Railroad ties can be purchased at most home improvement stores.

Set railroad ties before the driver arrives

If your delivery site is dirt, we recommend keeping the container off the moist ground using 2 railroad ties — one at each end. This will prevent the C-channel and the cross members from rusting out.

The railroad ties should be set in place and leveled with no low corner before the driver arrives.

Assist with railroad ties during the delivery

Handling railroad ties will require two strong people. Make sure there are two people on- site to assist with railroad tie placement as some drivers cannot help due to liability reasons.

When the driver arrives, pull away 1 railroad tie so the driver can lower the container to the first railroad tie. The delivery driver will pull forward and before the container comes off the truck, place the second railroad tie in place.

Contact Information – The shipping container delivery company requires two contact phone numbers, and one must belong to the site contact. There is a possibility that the driver will postpone the delivery if they cannot reach the customer by phone before the delivery so it’s important to provide more than one number.

Gated or secured entrance – If the driver will be required to enter or check in at a specific gate you must provide pertinent information such as gate number, site contact, required I.D. or proof of insurance, and rules regarding weapons for high security or military locations.

Site contact must be on the premises – We require the customer or a site contact to be onsite at the tie of the delivery to direct the placement of the container. If there is no person at the site to accept the container and the customer authorizes the driver to deliver the container anyway, Onsite Storage will not be responsible for any misplacement of the container.

Workers onsite – We recommend that you do not have workers on standby on the day of the delivery to load the container as delivery timing is uncertain and may result in loss of wages that Onsite Storage will not be responsible for.

Drivers right of refusal – The drivers will do their best to place the container in the desired location. It is the drivers right to refuse to place the container in a location where they feel it may cause harm to themselves or their property.

Cancelation policy – On-Site Storage Solutions uses independent third-party trucking companies to deliver containers. Their livelihood is dependent on making their scheduled deliveries. They require a minimum of 48-hours of advanced notice for cancelations. If you need to cancel within less than 48 hours you will be charged a $300 cancelation fee per delivery. Cancelations due to weather are excluded.

The key to a smooth shipping container delivery is preparation and communication. If you feel you are unable to meet these delivery requirements or have any questions it is best to contact your Onsite Storage Solutions agent to decide whether special accommodations will be necessary.

Containers are transported or moved using specialized trailers known as Shipping Container Chassis. These chassis typically accommodate containers that are 20, 40, or 45 feet in length.

The cost of moving a shipping container within the same city of the depot is approximately $5 per mile for a short distance. However, the actual price may vary based on factors such as the size of the container, the route taken, and the location.

Transporting shipping containers is possible with various types of trucks such as tilt bed truck, flatbed truck, or a truck equipped with a container chassis.

Yes, technically you can ship your own container, but it requires a high level of expertise. Shipping containers involves understanding operational aspects like lifting, positioning, and grounding. Without professional training and experience, this process can be challenging and risky. Thus, it’s typically recommended to employ professional shipping services.

Shipping containers are delivered using specialized trucks such as flatbed, tilt-bed, and roll-off trucks. The flatbed trailer is designed to accommodate the size and weight of shipping containers, allowing easy transport over long distances.

To unload shipping containers, sufficient clearance in height and width is essential. A straight distance of 120 feet is required, with a height clearance of 14 feet, increasing to 21 feet during unloading. Additionally, a width clearance of 13 feet is necessary. The ground must be dry and firm to support the weight of trucks, often exceeding 30,000lbs.

Ⓒ 2024 On-site Storage Solutions | All Rights Reserved

We use location cookies to provide optimized services based on your area. You can choose to allow or deny this.